|

GENERAL DESCRIPTION

|

|

An Allied brochure on Foamed

Concrete is Available for

Downloading in

.pdf Form - |

|

May, 2014 |

|

1. Allied Foam Tech has been

awarded by USCA as the best chemical machinery & equipment

manufacturer in Montgomeryville, Pennsylvania in 2009-2011, 2013

& April, 2014. |

|

2. May, 2014- Our

innovation (click here for details) on "Wood-like Flexible Cementitious Foam"

received silver medal of the 2014 Edison Awards and we are joining

the rank of winners like Apple, 3M, Boeing, and other current

and past winners.

Edison Awards will promote Allied's innovation to a wide

variety of business press and media outlets. |

|

|

|

HUMIDITY

RESISTANT FOAM GYPSUM CEILING TILES |

|

Moisture & Humidity Resistant Foam Gypsum Ceilings by Client Using Allied Licensable

Cross-linking Foam Technology |

|

|

|

|

|

|

|

|

|

1.5-1.7 lbs./ft2 at 1/2" thick with acoustic

& fire resistance properties

|

|

FLEXIBLE CEMENT PANELS, FLEXIBLE CEMENT SHINGLES &

FLEXIBLE CEMENT BOARDS |

|

TECH LICENSE

OPPORTUNITIES

(January, 2014) |

|

Allied Foam Tech, through its ~ 20 years

of internal R & D effort and global industrial

experience in building trade, has developed a wide range

of proprietary lightweight building composites, process

and performance properties based on its patent pending

lightweight fiber cement technologies and composites.

Major building product manufacturers interested in

licensing rights

please click here. |

|

A few highlights are given below: |

|

·

1.

Superlight and flexible cement sheets

with great adhesion characteristics, high water

resistance, and high impact and compressive strengths

(MOR > 750 psi, indented compressive strength >

1,000 psi and 24 inches static water column test > 48

hours).

·

2.

Lightweight and flexible (roll forming)

decorative sheetings for various exterior or interior

wall wrap or wall covering applications.

·

3.

Asphalt-free flexible

shingle (110-130 mils) and underlayment materials (50 to

70 mils) with UV resistance, freeze-thaw stablility,

great coating and granule adhesion, tear strength and

lightweight that is not available in the current roofing

industry.

·

4.

Foamed curable thin

sheets, with their uv stability, flexibility, high

tensile strength, great adhesion to metal and water

resistance, are very adaptable for the manufacture of

roofing shakes and metal roof tile composites.

·

5.

Lightweight flexible

cementitious coatings for the various commercial foam

boards such as polystyrene and polyurethane foam boards.

·

6.

Lightweight cast stones

with high mouldability (low slump), good fire resistance

and quick demolding behavior, high tensile strength and

adhesion for pigment and coloring should be very

suitable for direct replacement of the various heavy

stone or other concrete cast stone products.

·

7.

The flexible

cementitious composites allows prefabricated or cast in

place sandwich panels of various kinds to be made.

Extrudable cementitous composites can also be engineered

allowing for friendly adaptation of the various

manufacturing process, curing and storage capabilities. |

|

|

|

|

|

ACOUSTIC CEMENT PANELS,

WATER PERMEABLE FOAMED CEMENT & FOAMED CONCRETE |

|

Click here

for QuickTime

Nov., 2014

Nov., 2014

The world's first foam cement and concrete with control

of % Open POREs vs Close POREs

*

economical porous material for all weather acoustic

panels *

*

WATER PERMEABLE FOAM CEMENT AND FOAM CONCRETE *

(acoustic

panels for highway, mine, tunnel, railroad, mass

transit, power plant, subway, marine vessel, airport,

heat pump) |

|

Mostly Open Pores |

Mostly Closed Pores |

|

|

|

|

|

|

Click here

for QuickTime

Nov., 2014

Nov., 2014 |

|

|

|

Such

foam cement can easily reach a compressive strength of >

270 psi at an air dried density of 29 pcf. |

|

*All the commercial

pervious lightweight cement systems rely their

permeability on either the very coarse open pores or the

interconnected capillaries derived from severe foam

collapse. Such cellular cement composites are typically

very low in compressive strength, e.g. 80 - 150 psi at

densities ~ 30 pcf. |

|

Foam concrete or lightweight concrete derived from Allied's

aqueous foams are suitable for both

precast and

cast-in-place

applications. Some of the highly insulative cementitious

foams at densities 48 kg/m3(3 pcf) to 645 kg/m3(40

pcf) or higher can be used as block fills, lightweight roof deck

and void-fill materials. Good strength characteristics with

reduced weight make lightweight concrete based on Allied's

aqueous foams suitable for structural and semi-structural

applications such as lightweight partitions, wall and floor

panels, and lightweight blocks. Cementitious foams derived from

Allied's premium systems are suitable for thin layer coating

applications where specific performance criteria are required.

Foamed concrete and foamed cement made with Allied's foam have very fine

pore structure, unlike that made with conventional proteinaceous and

surfactant foams. The pore structure of Allied's foams hardly show any

sign of deterioration as the density of the foamed cement decreases to

below 160 kg/m3 (10 pcf). At densities below 160 kg/m3,

the pore texture of foamed cement derived from conventional foam agents

becomes so coarse that most of them show severe structural collapse.

The dynamic nature of Allied foam systems allows different foam rheology

to be incorporated into the host cement/concrete matrix to satisfy a

wide range of slump loss requirements.

The inert nature of Allied foam

systems makes them

compatible with different kinds of aggregates, fillers,

extenders, retarders, accelerators, colorants, hydraulic

inorganics and many other additives. |

|

|

|

|

|

|

Allied Low Slump CEMENT Geofoam/GEOTECHNICAL

FILL - A GAME CHANGER

in

the Geofoam MarkET |

|

Allied "Cement Geofoam"

will greatly simplify the application and cost relative

to the "Expanded Polystyrene Geofoam" |

|

Highway Embankment, Bridge Underfill, Landscape

Architecture, Slope Stabilization, Levees, Airport

Runway, Road Construction |

|

Allied 5-15 pcf Fiber Low Slump Cement Geofoam |

Conventional 0.7 - 2 pcf EPS Geofoam |

|

> > |

>> >> |

> > |

| Low load on the

surrounding soil |

Low load on the

surrounding soil |

| Casting with a continuous low slump pour |

stacking of

individual blocks delivered on site |

| Shape & conform

to the landscape easily with the low slump cast |

Shape & conform

to the landscape easily with the precast blocks |

| Foam formation onsite

through compressed air and foam agent |

Huge number of

eps blocks have to be delivered on site |

| No fire hazard,

good solvent resistance |

Fire hazard,

lack of solvent resistance(membrane needed) |

| Intimate soil

contact with easy surface leveling and slope build-up |

Sand leveling

or other means needed for block alignment |

| Uniform and

bulk cast without gap formation or concerns for

buoyancy, individual piece heaving/floatation

|

Geomembrane or

separation layer needed to avoid uneven block floatation

or dissolution by organic liquid seepage. |

| Uniform &

continuous pour/cast with ease of contour buildup

|

Interblock

locking plates may be needed for block alignment |

| Wide range of

density and strength possible:5 - 50 pcf, 2 >500psi |

Density and strength are limited - 0.6 - 2.0 pcf, 2-10

psi. |

|

For more details click here. |

|

Allied Low Slump Cementitous

Geofoam - easy to shape & conform to the landscape

without moulds |

|

Cast w/o

Mould - Wet |

Cast w/o

Mould - Dry (d=25 pcf) |

Mould-free

Cast- Wet |

Mould-free

Cast - Dry (d=8 pcf) |

|

|

|

|

|

Fiber

Re-enforced Allied Cement Geofoam vs EPS Geofoam - Very

Comparable Toughness During Compression |

|

|

|

* Higher

compressive strength can easily be reached by a slight

density increase of Allied Cement Geofoam, e.g. 85 psi

at a density of 16 pcf. |

|

|

|

|

November, 2013 |

|

GEOPOLYMER FOAM

|

| Density = 2.9 pcf (47 kg/m3),

R Value = 3.84 ft2oFh/(Btu in) |

|

|

|

Highlights

on Allied’s WORK with Foamed DECORATIVE STONES,

Blocks and Foamed Panels

|

| (WE

PROVIDE FOAM PRODUCTS, FOAM MACHINERY AND TECH SERVICE IN

PROCESS & MIX DESIGNS) |

| Autoclaved aerated

concrete (AAC) was introduced in Europe over half a

century ago as a lightweight construction material. The key

features AAC has over conventional foamed concrete are significantly better strength and lower shrinkage/cracking.

However, most of the attempts over the last few decades to

introduce AAC to the US either failed or hardly made any signifcant

impact to the construction industry. The million of dollars of capital investment needed for

the manufacture of AAC over the

conventional precast plant is just one of the many reasons

reported in the literature. |

| Freshly

prepared decorative stone panels with low shrinkage and

non-cracking features are shown below: |

| 3.6

feet x 2.6 feet (1.1 meters x 0.8 meters) |

| Total

weight = 28 pounds or 12.7 kg. |

|

|

| (the

blue center block was acid-etched showing the blue

decorative sand texture underneath) |

|

| Dimensions

of individual panel = 22" x 8" w. thickness of

0.25"-1.25" (0.56meter x 0.2meter w. thickness of

1.6cm-3.2cm) |

| (weight

per panel = 3.5 pounds (1.6 kg.) |

|

|

|

|

|

Extrudable Foam Cement Blocks |

| Freshly prepared

cement/aggregate bricks/blocks derived from Allied's specialty foams

with high slump loss may even be extrudable and thus amenable for

mass production. A freshly cast foam brick at 37 pcf (600

kg/m3) without using any mould is shown below: |

| Freshly

Made Foam Cement Brick w. High Slump Loss (density = 37

pcf) |

Extruded

Foam Cement/Ltwt Aggregate Composite (density = 40 pcf,

compressive

strength = 660 psi (4.6 MPa)) |

Instantly

Demolded Cement/Ltwt Aggregate Composite (density = 31 pcf,

compressive

strength = 460 psi (3.2

MPa)) |

| (a

mould-free cast) |

(low

pressure extrusion) |

(demolded

in < 1 minute) |

|

|

|

| |

| Highlights

on Allied’s WORK witH Geotechnical engineering, LANDSCAPE ARCHITECTURE AND SLOPED ROOF

DECK |

Composites with

Allied’s premium foamed cement/high

slump-loss/high strength 35 pcf foamed cement allows greater and

simpler landscape architecture and roof deck designs not achievable

by any conventional cellular concrete.

1. Geotechnical Engineering &

Landscape architecture

A. conventional

cellular concrete - conventional 35 pcf LDCC

(Low Density Cellular Concrete) with

shaved expanded polystyrene blocks.

Very limited slope

negotiation for conventional cellular concrete – less than

˝ inch drop per 10 feet span.

Very limited slope

negotiation for conventional cellular concrete – less than

˝ inch drop per 10 feet span. |

Geofoam/styrofoam blocks

of various sizes/shapes are needed to create artificial

slopes.

Geofoam/styrofoam blocks

of various sizes/shapes are needed to create artificial

slopes. |

Labor intensive and slow

process.

Labor intensive and slow

process. |

B. New and flexible

designs with Allied’s high

slump-loss foamed cement

^ back to top

Highly sloped landscape with > 1 feet drop per 10 feet span can

easily be achieved.

Highly sloped landscape with > 1 feet drop per 10 feet span can

easily be achieved. |

The use of Geofoam/styrofoam blocks is significantly reduced

or totally eliminated.

The use of Geofoam/styrofoam blocks is significantly reduced

or totally eliminated. |

Labor savings and faster process.

Labor savings and faster process. |

|

| High Slump

Loss Foamed Cement/Lightweight Aggregate

Composites with Low Shrinkage at a Dry Density

of 35-50 pcf (565 - 806 kg/m3) |

|

|

|

|

| >

2.5 feet drop per 10 feet span (1V/4H) |

Full

Size Air Conditioner Pad From High Slump Loss/Low Shrinkage

Foamed Cement Composite |

|

(dry density = 35 pcf) |

(dry density = 48 pcf) |

2. Improved Foamed Cement Roof

Deck Designs

Highly sloped industrial

and residential roofdecks or roofings become possible with Allied's

high slump-loss foamed cement product and mix design.

Allied's stable foam with

high slump loss can be applied directly on corrugated metal sheets

of new or repaired roofs without foam dewatering and possible water

leakage to the interior structure of the floors underneath while

such problems have always been associated with conventional cellular

concrete roof decks.

Allied's stable foam with

high slump loss can be applied directly on corrugated metal sheets

of new or repaired roofs without foam dewatering and possible water

leakage to the interior structure of the floors underneath while

such problems have always been associated with conventional cellular

concrete roof decks.

Using Allied’s 35pcf/10 pcf foamed cement

composite as roof deck structure will

achieve the right combination of thermal insulation and light weight

like

conventional cellular concrete/styrofoam blocks but with appreciable

labor and time savings and the flexibility in roof deck designs with varied shapes

and contours not achievable before.

Using Allied’s 35pcf/10 pcf foamed cement

composite as roof deck structure will

achieve the right combination of thermal insulation and light weight

like

conventional cellular concrete/styrofoam blocks but with appreciable

labor and time savings and the flexibility in roof deck designs with varied shapes

and contours not achievable before.

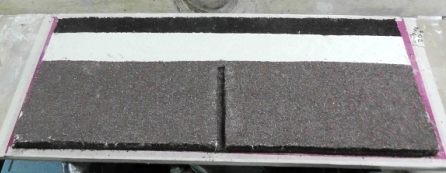

Comparison of

Roof Deck Composites from Allied's Foamed Cement Composite &

Conventional Foamed Cement/Expanded Polystyrene Board Composite.

|

|

|

|

|

|

28 DAYS STRENGTH

PROFILE AT 55 - 80 PCF (890 - 1,290 Kg/M3) -

loadbearing

and semi-structural.

|

|

(The following data are derived from

mix designs that may have different slump loss characteristics from

that at 30 - 60 pcf)

|

| Density

(Air Dry) |

Compressive

Strength |

|

(pcf) |

(Kg/M3) |

(psi) |

(MPa) |

|

56 |

900 |

1,200 |

8.2 |

|

65 |

1,040 |

1,480 |

10.2 |

|

69 |

1,110 |

1,700 |

11.7 |

|

74 |

1,190 |

2,300 |

15.9 |

|

76 |

1,240 |

> 2,500 |

> 17.2 |

|

|

|

|

COMPOSITE BLOCKS,

PANELS

-

non-loadbearing, low-load bearing

& insulative.

|

|

Even at densities < 20 pcf, the

strength development of Allied's foam/lightweight aggregate

composites allows <24 hours demolding time while still

maintaining good handling characteristics (all three blocks shown

below were demolded in 18-24 hours and were immediately saw-cut to

proper size)

|

|

|

|

| Fiber

Re-enforced Foam Cement Panels (50 pcf) |

Held in Air -

1.5 inch thick |

|

PERFORMANCE

| Some

Performance Features of Concrete and Cement Incorporating Allied's

Foam Systems: |

|

Consistent and fine pore texture at different densities

Low water uptake

Hight early and 28 day compressive strengths

Good thermal and acoustic properties

Wide range of rheological, adhesive and thin-set properties

|

|

The excellent

stability of Allied's foam products is demonstrated in the following pictures

of lightweight cement and concrete:

|

Foamed Cement

Using Allied AFT-400

Density = 0.24 g/cc (15 pcf)

|

Foamed

Cement

Using Proteinaceous Foam

Density = 0.24 g/cc (15 pcf)

|

|

|

|

fine

pores

|

coarse pores

|

|

|

Strength Development and Water

Uptake of Foamed Cement

|

|

Allied foams are compatible with different kinds of cement, fly ash, sand/aggregate fillers,

retarders, accelerators and water reducers. The AFT-400 series of foam reagents provide

cement and concrete with very low water uptake. Cementitious foams at densities as low as one tenth (1/10) that of dense concrete will still maintain lower than 15%

(by volume) water uptake in a 24 hour water immersion test. |

|

The following table shows some typical strength and water uptake characteristics

of a lightweight cement formulation using Allied AFT-400: |

FOAMED

CEMENT FORMULATION WITH AFT-400 - Strength Development and Water

Uptake

|

Density of Foamed Cement

(in

gram/cm3) |

Compressive

Strength |

24

hour Water

Uptake |

| After

24 Hours |

After

28 Days |

(volume/volume) |

| 0.74

(oven

dried) |

468

psi |

825

psi |

<

5 % |

| (3.25

Mpa) |

(5.3

Mpa) |

|

|

| | | |